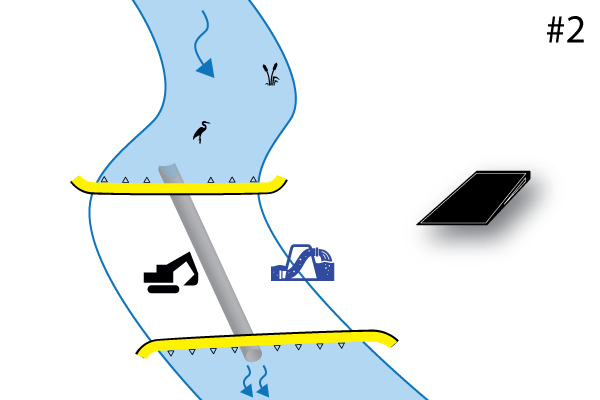

# 2 | Dewatering between 2 cofferdams

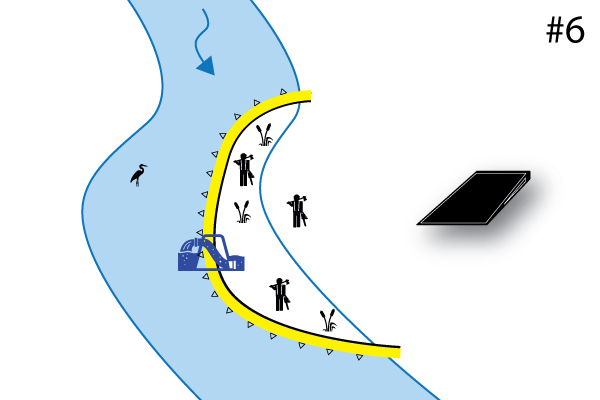

Canals, moats, small rivers: with this installation, large areas can be drained with a reduced total length.

This type of installation is recommended for narrow, gently sloping streams. The flexible cofferdams are installed by placing the hinges “back to back”.

Remove river mud/vase

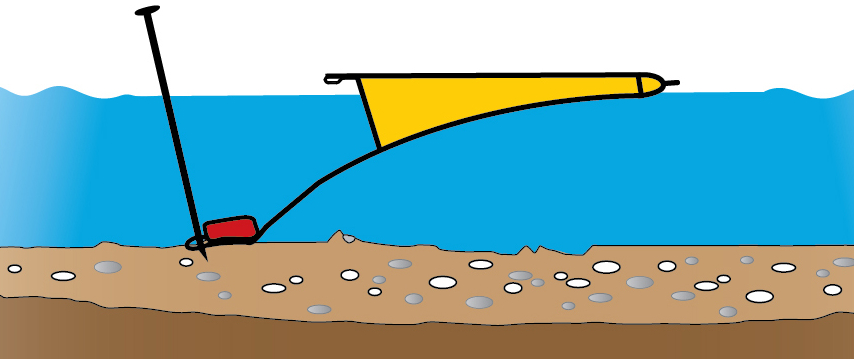

It is imperative to clean the bottom of the river, where the cofferdams will be placed, otherwise there is a risk that their stability will be compromised when filling (hydrostatic pressure). If the frictional forces between the backdrop and the ground are insufficient, the dam may begin to slip.

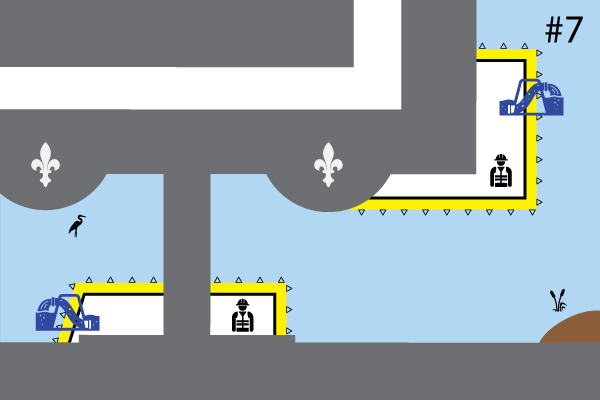

Installation methods depending on the type of watercourse

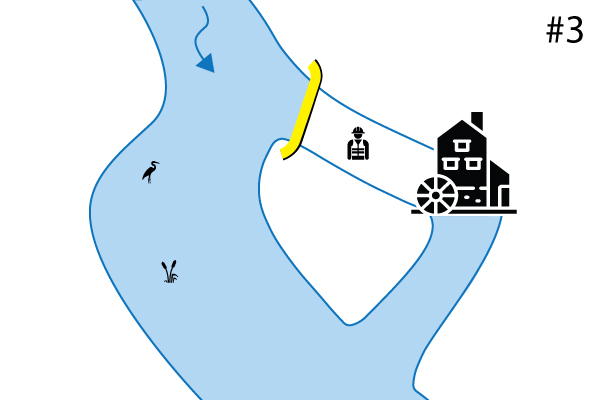

- Installation in white water

We first install the upstream cofferdam (see case #1, vertical cofferdam). The downstream cofferdam can generally be lower. The upstream flow can be diverted through a pipe laid under the flexible coffer dams or through pumps. - Installation in stagnant water

In calm water, the cofferdams are pre-positioned by anchoring the leading edge to the bottom of the water. Mooring is done using stakes placed in the metal rings on the leading edge to prevent movement of the canvas until the cofferdam is fully pressurized by pumping.

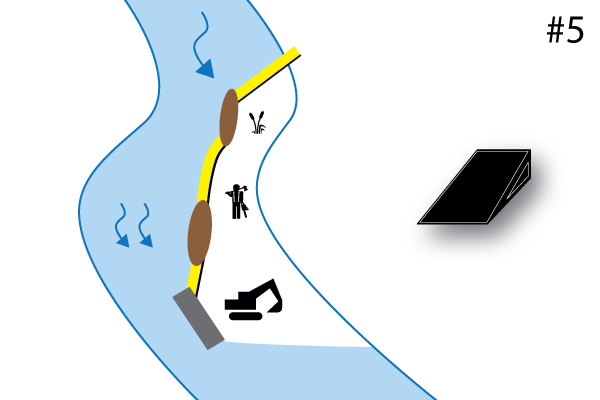

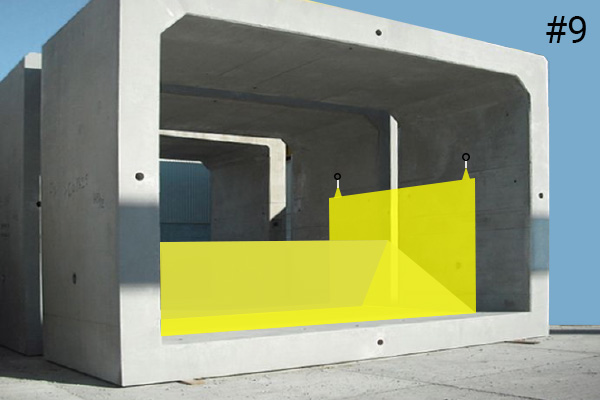

Dewatering / Exhaustion of the construction site

In practice, there are generally 3 phases.

- At the beginning, very gradual drop in the level of the area to be dewatered. The cofferdam canvas is only partially pressed against the ground, the waterproofing is partial, hence the importance of good ballasting on the leading edge.

- Then the drop in level accelerates as the cofferdam builds up pressure.

- The last third is often the one that requires more pumping power, especially if the height of the cofferdam is important and the soil is porous. Exsurgences can occur in the area to be dried according to the principle/law of communicating vessels.