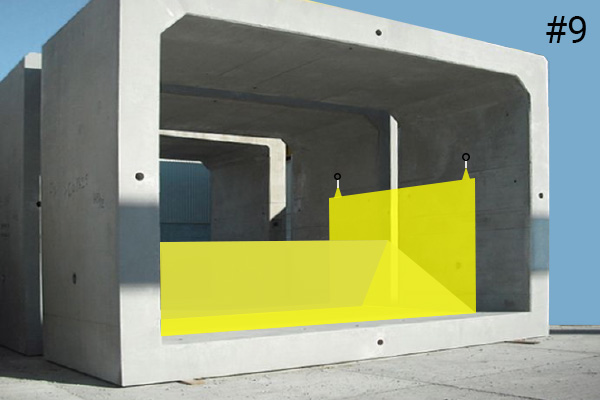

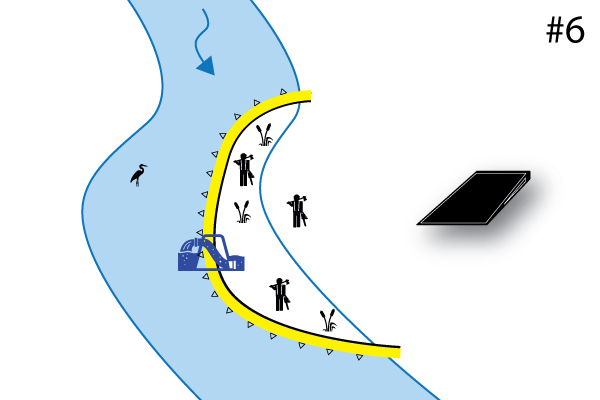

Attachment points at both ends and reinforcement of ground roughness

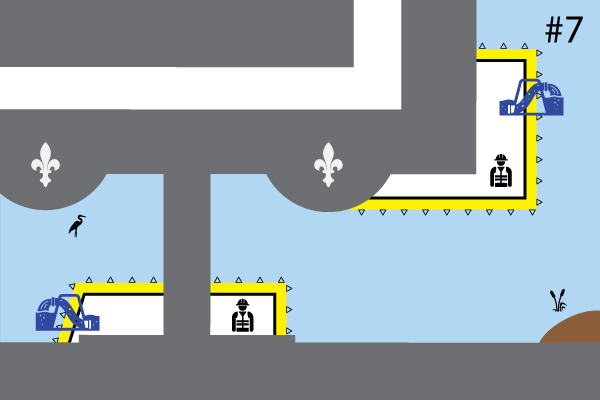

Installation in a frame is more difficult because you cannot operate from the bank of the stream.

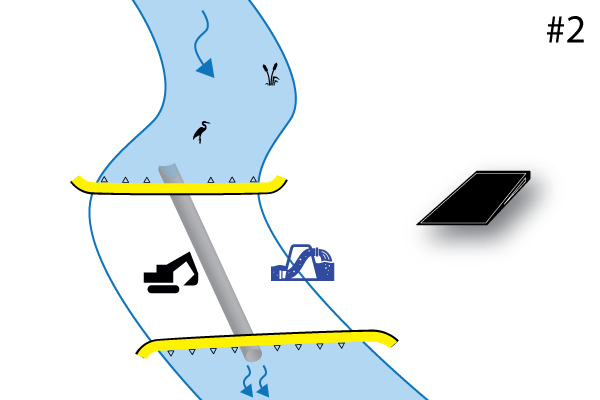

The laying area must be prepared before deploying the cofferdam.

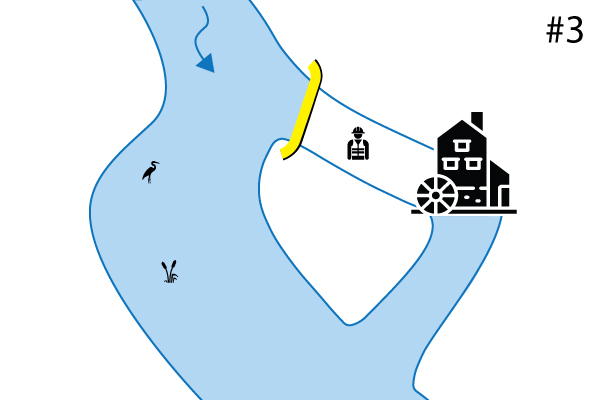

The deviation can be done by pipeline under the dam (See Case # 1) or by a spillway placed on the edge of the ridge (See Video).

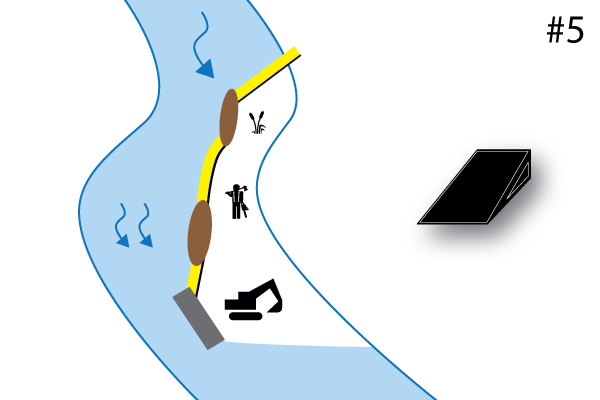

The stages of the Maneuver

- Clean the laying surface

- Prepare 3 anchor points on each wall

- Lay logs of gravel on the ground to increase the friction forces

- Route the flexible cofferdam

- Unroll the cofferdam

- Unfold the canvas. Please note that the leading edge must always be kept out of the water!

- Hang the 4 angles of the flexible cofferdam on the walls

- Position the canvas correctly between the two walls and over the sandbags

- Place the leading edge at the bottom of the water. Coordinated action!

- Check that the canvas goes correctly, without tension, on each side to the wall.

- Ballast the leading edge and angles

- Ridge edge: place the clamps in the corners to avoid creases and position the flotation accessories

- Fixing the leading edge against the walls